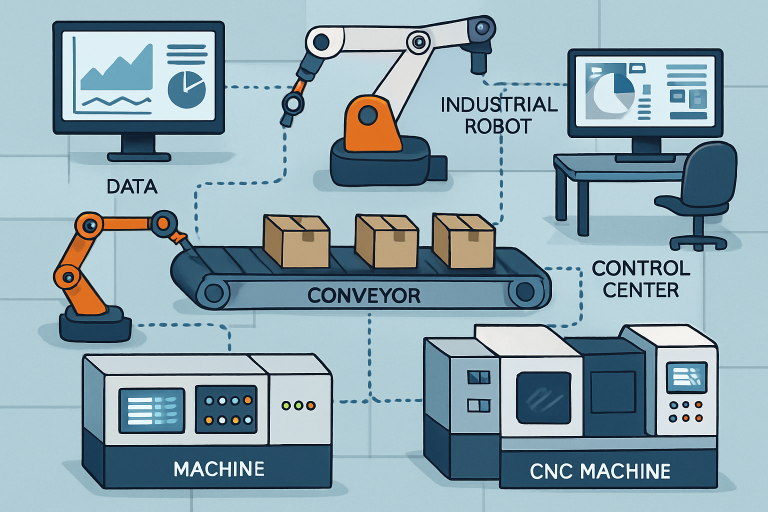

The evolution of manufacturing has always been driven by the ability to gather and utilize information effectively. In today’s dynamic environment, manufacturers are increasingly turning to real-time data to keep pace with rapid shifts in demand, supply chain interruptions, and operational inefficiencies. The use of production monitoring software has become a linchpin, enabling organizations to gain visibility and control over every aspect of their factory floor in real-time. Access to real-time data means decisions are no longer made on yesterday’s insights. Manufacturers can now monitor assets, performance metrics, and workflows as events unfold. This shift enables immediate action, allowing companies to reduce downtime, enhance product quality, and achieve remarkable consistency. It is a decisive competitive advantage, transforming everything from product manufacturing to the speed of issue detection and resolution. The integration of live data streams into existing manufacturing software and machinery also accelerates innovation. Forward-thinking companies are using real-time visibility to trial new processes, optimize planning, and predict maintenance needs, ultimately enabling them to adapt more rapidly to market changes.

This approach not only boosts productivity but also drives sustainability and waste reduction. By providing operators and leadership teams with actionable information at their fingertips, the manufacturing sector can transition toward leaner operations and more sustainable outcomes.

Table of Contents

The Role of Real-Time Data in Manufacturing

Real-time data acts as the nervous system of contemporary manufacturing businesses. Sensors embedded throughout facilities constantly gather telemetry from machines and production lines. This data is analyzed immediately, feeding critical insights to teams responsible for ensuring smooth operations. Whether it’s identifying a bottleneck on a specific line or understanding how energy is consumed daily, instant information empowers manufacturers to solve problems before they escalate proactively. With real-time data, manufacturers can transition from reactive to predictive management. This means moving away from waiting for failures and delays to continuous improvement and risk mitigation—dramatically minimizing unplanned downtime and maximizing resource allocation.

Key Technologies Driving the Shift

- Internet of Things (IoT): IoT technology connects sensors and equipment, enabling automatic tracking, logging, and analysis of every relevant manufacturing metric.

- Artificial Intelligence (AI): Machine learning algorithms process high-volume data streams to highlight patterns, spot anomalies, and guide next-step decisions.

- Digital Twins: By creating virtual replicas of physical assets, digital twin technology allows for precise simulation, process optimization, and scenario analysis.

These rapidly advancing technologies facilitate a closed loop of observation, analysis, and improvement, enabling manufacturers to operate more intelligently and autonomously. As noted by McKinsey & Company, digitization can increase productivity and flexibility across industrial operations.

Benefits of Real-Time Data Integration

- Enhanced Decision-Making: Access to real-time information enables teams to act swiftly and update plans as necessary.

- Predictive Maintenance: Continuous monitoring of equipment enables the forecasting of potential breakdowns and the scheduling of repairs with minimal disruption.

- Quality Control: Problems can be detected as soon as they occur, ensuring quality is maintained at every step of the manufacturing process.

The sum of these benefits is significant operational cost savings, a reduction in scrap and waste, and improved customer satisfaction due to a more reliable production process.

Challenges and Considerations

Real-time integration isn’t without hurdles. One of the biggest challenges is managing the sheer volume of data generated throughout extensive operations. Without the right backend systems and analytic frameworks, data overload can swamp even the most sophisticated organizations.

- Data Overload: Manufacturers must sift through terabytes of information, requiring advanced analytics platforms to provide clarity and actionable insights.

- Security Concerns: With an increasing number of devices and applications online, cybersecurity becomes critical for protecting sensitive competitive information and production details.

- Integration Complexity: Upgrading or aligning legacy systems with state-of-the-art data tools can require significant technical effort, planning, and investment.

Thinking ahead and building a data strategy that incorporates robust security and scalability is essential to overcoming these obstacles and realizing the full potential of real-time operations.

Case Studies of Successful Implementation

- BMW Group: BMW utilizes real-time data integration across all stages of production to streamline operations, improve innovation, and tailor solutions for specific business requirements. This approach has yielded significantly faster problem-solving and enhanced manufacturing flexibility.

- German Factories: Manufacturers in Germany that employ real-time analytics have seen up to 30% reductions in production downtime. These results demonstrate the transformative potential of data-driven decision-making in traditional and advanced manufacturing environments.

Steps to Implement Real-Time Data Strategies

Assess Current Systems: Begin with a thorough evaluation of current processes and IT infrastructure to surface integration gaps and opportunities.

Invest in Technology: Upgrade equipment and select platforms offering IoT, AI, and digital twin capabilities. Choose scalable and secure solutions to future-proof your operations.

Train personnel to build a culture of data literacy and continuous learning, ensuring staff possess the skills to realize the value of real-time insights.

Establish Security Protocols: Prioritize cyber defenses, control access, and regularly audit systems to maintain data confidentiality and integrity.

Successful implementation requires commitment from leadership and buy-in from stakeholders throughout the organization, as well as a clear vision for digital transformation.

Conclusion

Real-time data is transforming manufacturing into a more agile, efficient, and quality-driven industry. Incorporating advanced technologies such as IoT, AI, and digital twins enables manufacturers to optimize every process, respond instantly to challenges, and continually improve the products they deliver. As real-time data becomes an operational imperative, manufacturers willing to embrace these technologies will be equipped to lead the industry into the future.