Table of Contents

Introduction

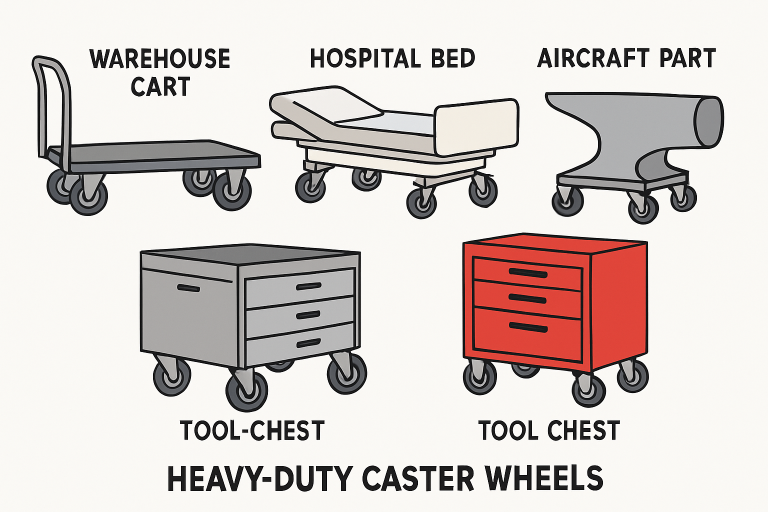

Heavy-duty casters are vital components in industries that require the efficient movement of large, cumbersome loads. Their robust construction and innovative design support various sectors’ logistics, operations, and safety. Heavy duty wheels can dramatically improve equipment mobility and operational ease, whether it’s a bustling warehouse or a high-traffic hospital corridor. The ability to move heavy machinery, inventory, or essential equipment with minimal effort translates to streamlined workflow, increased productivity, and a safer working environment where the risk of injuries from lifting or pushing is significantly reduced. Investing in the proper mobility solutions offers long-term savings and ensures compliance with regulatory safety standards, both critical factors in achieving operational excellence.

Selecting high-quality heavy-duty casters is more than a matter of convenience; it’s a fundamental decision that impacts efficiency, asset longevity, and workplace safety. As industries become increasingly complex, the demands on equipment mobility also rise. With a focus on advanced materials, superior performance, and application-specific features, heavy-duty wheels are engineered to thrive under challenging conditions. They offer resistance to impact, corrosion, extreme temperatures, and chemicals—qualities essential for long-term service life in both indoor and outdoor environments. This level of engineering makes heavy-duty casters indispensable for anyone involved in handling substantial loads, ensuring mission-critical equipment is always ready to move when needed.

Manufacturing and Warehousing

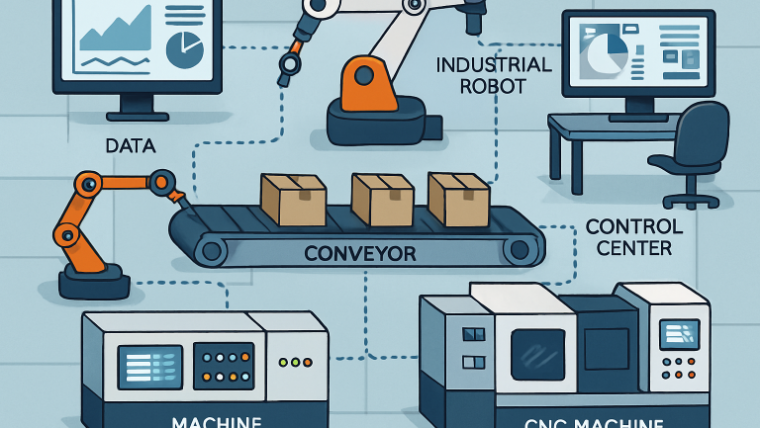

In manufacturing and warehousing environments, efficiency and safety are fundamentally rooted in swiftly and reliably moving large quantities of cumbersome items. Heavy-duty casters are central in pallet jacks, trolleys, storage racks, and industrial carts, enabling operators to transport goods throughout high-capacity facilities more easily. Their durable design significantly reduces manual handling, minimizing the risk of musculoskeletal injuries while streamlining loading and unloading processes. Over time, this results in a notable reduction in worker fatigue and lost-time incidents, contributing directly to improved operational performance.

For instance, in modern distribution centers filled with intricate racking systems, casters are integral to automated storage solutions, allowing entire shelving units to be repositioned easily for layout adjustments, seasonal shifts, or maintenance needs. As supply chains become more agile in response to market demand, high-quality casters are critical for facilitating fast turnarounds and just-in-time inventory systems. This adaptability is crucial as e-commerce growth drives new expectations for speed and flexibility in warehouse operations.

Healthcare and Medical Facilities

In healthcare settings, swift and secure movement is necessary not only for life-saving equipment but also for the safe transport of patients. Heavy-duty casters are found on hospital beds, mobile medical carts, portable imaging machines, and anesthesia or emergency crash carts. These environments require specialized features in casters, such as anti-static coatings to prevent sparking, non-marking wheels to protect sterile floors, and easy-swivel mechanisms for rapid directional changes. Smooth and reliable mobility can enhance emergency response times, allow safe navigation through tight spaces, and reduce the risk of cross-contamination by facilitating quick cleaning and sterilization routines.

With healthcare demands ever-rising, casters help accommodate shifting needs, be it quickly converting operating rooms or transporting heavy medical equipment between departments. This agile mobility supports improved patient care, enhances staff efficiency, and creates a more adaptable healthcare system.

Aerospace Industry

The aerospace industry relies on precision and safety in handling substantial and delicate components, such as airplane fuselages, wings, and engine sections. Heavy-duty casters built to support several tons must also offer precise and controlled movement to transport parts safely across factory floors and within maintenance hangars. Engineering challenges in this sector often require advanced wheel materials—such as specialized elastomers or high-grade steel—and locking mechanisms that can secure loads during movement or assembly.

Aerospace manufacturers and service providers must meet strict regulatory and quality standards, making advanced caster technology essential to production and ongoing aircraft servicing. These wheels often feature additional safety elements like dual brakes and directional locks to prevent unplanned rolling or shifting during critical processes. Their role is crucial in environments that value productivity and safety at the highest level.

Construction and Engineering

Construction sites present a unique challenge for mobility solutions, with outdoor environments often including debris, uneven ground, and shifting weather conditions. Heavy-duty casters equipped with reinforced polyurethane or solid steel treads are designed to handle these rigors, providing essential mobility for scaffolding units, job-site tool chests, heavy-duty carts, and portable modular offices. Their resilient construction, including corrosion- and impact-resistant finishes, extends their lifespan in harsh settings where standard wheels would quickly degrade.

Reliable casters not only increase project efficiency by enabling quick resource relocation but also bolster safety by reducing manual lifting and allowing workers to move bulky items securely with less effort. Their dependable performance is key to meeting tight construction timelines and compliance with jobsite safety standards.

Automotive Industry

The automotive industry depends on seamless transitions between vehicle and part assembly stages. Heavy-duty casters and wheels facilitate the efficient movement of vehicles, engines, transmissions, and tooling fixtures along assembly lines and between workstations. Their robust construction allows automotive plants to manage multi-ton loads, supporting just-in-time manufacturing techniques that reduce storage requirements and optimize production flow. Without reliable casters, expensive downtime and operational bottlenecks would be far more common, undermining productivity and worker safety.

Beyond assembly lines, these casters are frequently found on maintenance stands, shipping containers, and parts carts, helping speed up repairs and streamline outbound logistics. Their versatility and strength are vital for an industry that values durability and flexibility at every production stage.

Retail and Commercial Spaces

Adaptability is essential for maintaining a fresh and inviting environment in the fast-paced retail and commercial spaces. Heavy-duty casters offer the strength needed to easily move heavy display units, furniture, and ample storage cabinets while maintaining a quiet operation that minimizes disruption to customers or clients. Their ergonomic designs make it possible to reconfigure sales floors, reorganize storage areas, or move cleaning equipment efficiently, enabling stores to quickly respond to changing layouts, promotional campaigns, or seasonal shifts.

Flooring protection is a key concern in these spaces, so non-marking and smooth-rolling designs prevent unsightly scratches or damage. The ability to relocate even the bulkiest fixtures ensures stores stay organized and visually appealing, while maintenance and cleaning crews can work unobstructed. Heavy-duty casters also play a role in back-of-house applications, such as kitchens, storage rooms, or stock areas, contributing to safety and streamlined workflows.

Conclusion

Heavy-duty casters have become indispensable across an increasingly diverse spectrum of industries, serving as the foundation for mobility, safety, and operational excellence in today’s fast-paced work environments. By carefully matching caster specifications—such as weight capacity, wheel material, and resistance to environmental factors—to each unique application, businesses can ensure smoother workflows, maximum asset protection, and a safer workplace for all personnel. Heavy-duty wheels will remain at the heart of innovation and progress as industries evolve amidst growing demand for speed and adaptability, propelling small and large-scale operations toward their goals.