Table of Contents

- 1 What Does Total Cost of Ownership Mean for Industrial Equipment?

- 2 Key Factors That Contribute to Lifetime Equipment Cost

- 3 Calculating TCO: Steps and Tools for Accurate Estimates

- 4 Why “Cheapest Upfront” Rarely Means Lowest Cost Over Time

- 5 Hidden Costs Often Overlooked in TCO Assessments

- 6 Extending Equipment Lifespan to Cut Down on Total Cost

- 7 Using TCO to Make Wiser Investment Decisions

- 8 Conclusion

What Does Total Cost of Ownership Mean for Industrial Equipment?

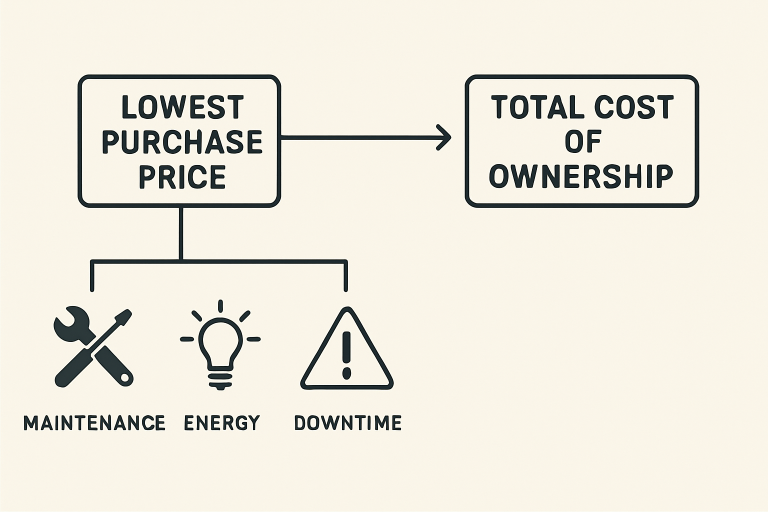

Industrial buyers today face stiff competition, tightening margins, and significant pressure to produce more value from every investment. This is why understanding the total cost of ownership (TCO) for industrial equipment has become a critical consideration—not just an accounting exercise, but a strategic necessity. Simply put, TCO is a holistic financial estimate that measures the entire lifecycle cost of owning and operating a piece of equipment. It extends far beyond the initial purchase price, encompassing installation, maintenance, energy use, and eventual decommissioning.

TCO helps purchasing teams and facilities managers make more informed decisions, ensuring that the selection of equipment contributes to long-term operational efficiency and reduces surprises down the road. If you’re sourcing machinery or parts, working closely with experienced Industrial suppliers in North Carolina can help you factor in these variables, ensuring your procurement process reflects the true investment required for each asset.

Key Factors That Contribute to Lifetime Equipment Cost

- Initial acquisition and installation costs: The equipment price, shipping, taxes, and installation setup are the most visible contributors—but not the only ones.

- Ongoing maintenance, repair, and parts replacement: Routine servicing, emergency repairs, and annual parts replacement costs can quickly increase over the years.

- Energy consumption and utility expenses: Efficient equipment models may be slightly costlier upfront, but they significantly reduce utility bills over time, contributing to savings and sustainability goals.

- Training and labor considerations: Some machinery requires specialized labor or frequent staff training, impacting operational costs and workforce efficiency.

- Downtime and productivity impacts: Frequent breakdowns or reliability issues can translate to lost output and higher costs, affecting both short-term revenue and long-term reputation.

Calculating TCO: Steps and Tools for Accurate Estimates

Calculating TCO starts with gathering reliable data about current and prospective equipment. Industry professionals employ frameworks like Net Present Value (NPV) and Life Cycle Cost Analysis (LCCA) to factor in obvious and hidden costs. Essential data points include maintenance logs, service contracts, warranty conditions, utility consumption ratios, and historical failure rates.

Several advanced software tools, such as SAP’s asset management module or dedicated TCO calculators, can process these numbers and output clear projections, allowing side-by-side comparisons of equipment models and brands. Leveraging these resources allows buyers to benchmark total costs and confidently justify investments to stakeholders.

Why “Cheapest Upfront” Rarely Means Lowest Cost Over Time

Choosing equipment based on the lowest purchase price is tempting, but case studies across manufacturing and process industries warn against this short-sighted view. For example, facilities that invest in lower-cost machinery often face a higher frequency of repairs, faster wear of parts, and greater downtime—all of which erode any perceived savings. Conversely, investing in robust, energy-efficient, and modular equipment can reduce TCO dramatically.

Hidden Costs Often Overlooked in TCO Assessments

- Sunk costs in storage, handling, and spare inventory: Inventory holding and storage fees can quietly consume budget, especially for spare parts that may never be used.

- Legal, regulatory, and certification fees: Compliance costs, such as safety inspections and certifications, often arise unexpectedly, particularly with imports or custom machinery.

- Disposal and decommissioning costs at end-of-life: Responsible recycling, hazardous material disposal, and equipment removal can be expensive, and must be anticipated at the outset.

Extending Equipment Lifespan to Cut Down on Total Cost

Preventive Maintenance and Smart Upkeep

Routine inspections and preventive maintenance schedules greatly extend equipment life and improve ROI.

Upgradeability and Modular Systems

Choosing platforms that support component upgrades or modular expansions helps your investment adapt to changing demands, reducing cost and waste over time. Frequently upgrading your P.E.T. compressor valve parts helps maintain consistent performance while preventing minor wear from escalating into larger system failures. This proactive approach supports operational efficiency and extends the overall lifespan of the equipment.

Benefits of Regular Equipment Audits

Annual equipment audits help identify inefficiencies, forecast upcoming maintenance, and inform future procurement decisions, further driving down lifecycle costs.

Using TCO to Make Wiser Investment Decisions

TCO is more than a technical metric—it’s an opportunity to align procurement with long-term stability and agility. Balancing short-term ROI with long-term value demands close collaboration between procurement, finance, and operations teams, ensuring every purchase supports broader business goals.

Industries such as advanced manufacturing demonstrate best practices by optimizing their supply chains through TCO thinking—favoring suppliers and partners that consistently offer the lowest lifetime cost rather than merely the lowest bid.

Conclusion

Understanding and applying the total cost of ownership transforms equipment purchasing from a short-term expense into a strategic investment. Industrial buyers can make smarter decisions that enhance productivity, reduce downtime, and improve long-term profitability by factoring in all lifecycle costs and hidden expenses. Organizations that prioritize TCO optimize their operational efficiency and gain a competitive edge by ensuring every piece of equipment delivers maximum value over its lifetime.